- Offer

- Offer

- System types

- System KAN-therm ultraLINE

- System KAN-therm Push

- System KAN-therm ultraPRESS

- System KAN-therm PP

- System KAN-therm PP Green

- System KAN-therm Steel

- System KAN-therm Inox

- System KAN-therm Steel Sprinkler

- System KAN-therm Inox Sprinkler

- System KAN-therm Groove

- System KAN-therm Copper

- System KAN-therm Tacker

- System KAN-therm Profil

- System KAN-therm Rail

- System KAN-therm TBS

- System KAN-therm WALL - the wet method

- System KAN-therm WALL - the dry method

- System KAN-therm Football

- KAN-therm InoxFlow

- KAN-therm Cabinets Slim & Slim+

- Installation types

- Heating and cooling installations

- Cold and hot tap water systems

- Underfloor heating and cooling systems

- Wall heating and cooling systems

- External surfaces heating and cooling systems

- Firefighting sprinkler system

- Technological and industrial systems

- Form-inquiry

- KAN-therm water supply distribution systems

- Examples of KAN-System mixer tap fixture branches

- Calculators

- KAN-therm SMART & BASIC+ Automation Systems

- New products in offer

- KAN-term with a new QB certificate.

- Download

- Guarantee of quality

- Reference objects

- About us

- Contact

Connectors/fittings

Tube couplings are provided with pressed-on tips with an O-ring seal or pressed-on tips with a female or male thread to PN-EN10226-1:

- knees, elbows and tees, pipe connectors,

- threaded connectors type GZ and GW and screw joints,

- approaches to receivers and fittings/fixtures,

Fittings are made of alloy steel (chromium-nickel-molybdenum) #1.4404, AISI 316L.

Fittings are made of alloy steel (chromium-nickel-molybdenum) #1.4404, AISI 316L.

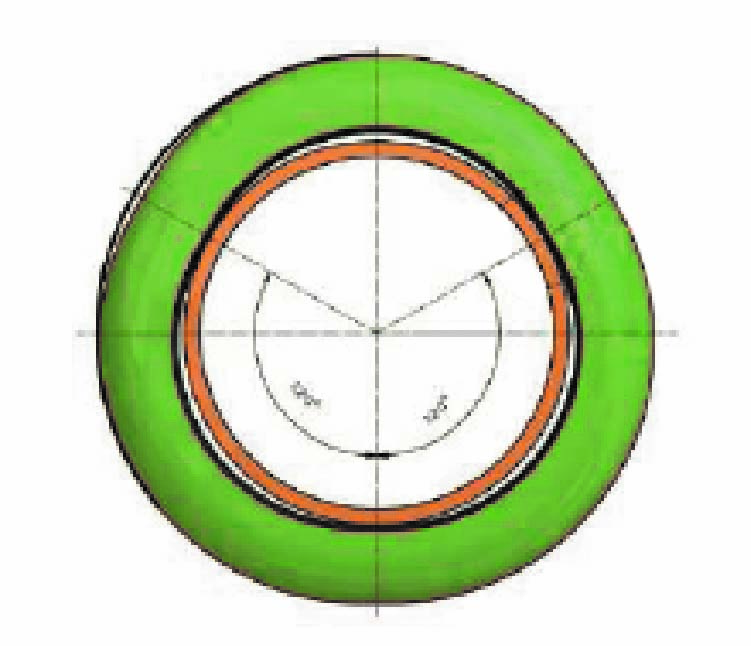

Sealings (O-rings)

The standard version of KAN-therm Inox and Inox System fittings is provided with EPDM rubber O-rings satisfying the PN-EN 681-1 requirements. For special applications they are delivered with Viton O-rings.

The table gives working parameters and application range for these fittings:

| Material | Colour | Working parameters | Application |

|

EPDM rubber |

black |

max. working pressure: 16 bar |

systems: |

|

FPM/Viton fluoric rubber |

green |

max. working pressure: |

systems: |

|

FPM/Viton |

grey |

max. working pressure: |

systems: |

All the fittings of KAN-therm Inox System within 15-108 mm dimensions contain LBP function (unsealed connections alert - LBP-Leak Before ultraPRESS).

.png)

Within 15-54 mm dimensions the function is realized by a specially designed O-rings. With a special grooves LBP O-rings provide optimal control over connections during the pressure test. Unsealed connections are leaky and therefore easy to locate.

.png)

Within 76,1 - 108 mm dimensions the LBP function is realized by an appropriate shape of fitting (pipe connector ovalisation).

The life of Inox system O-rings was tested by the DVGW Institute and according to these test this life should not be shorter than 50 years.

Copyright © 2017 KAN Group | All rights reserved. Privacy policy and important information concerning cookies.