- Offer

- Offer

- System types

- System KAN-therm ultraLINE

- System KAN-therm Push

- System KAN-therm ultraPRESS

- System KAN-therm PP

- System KAN-therm PP Green

- System KAN-therm Steel

- System KAN-therm Inox

- System KAN-therm Steel Sprinkler

- System KAN-therm Inox Sprinkler

- System KAN-therm Groove

- System KAN-therm Copper

- System KAN-therm Tacker

- System KAN-therm Profil

- System KAN-therm Rail

- System KAN-therm TBS

- System KAN-therm WALL - the wet method

- System KAN-therm WALL - the dry method

- System KAN-therm Football

- KAN-therm InoxFlow

- KAN-therm Cabinets Slim & Slim+

- Installation types

- Heating and cooling installations

- Cold and hot tap water systems

- Underfloor heating and cooling systems

- Wall heating and cooling systems

- External surfaces heating and cooling systems

- Firefighting sprinkler system

- Technological and industrial systems

- Form-inquiry

- KAN-therm water supply distribution systems

- Examples of KAN-System mixer tap fixture branches

- Calculators

- KAN-therm SMART & BASIC+ Automation Systems

- New products in offer

- KAN-term with a new QB certificate.

- Download

- Guarantee of quality

- Reference objects

- About us

- Contact

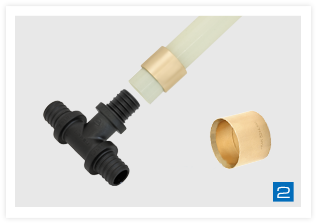

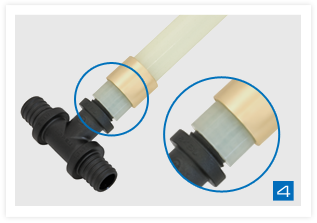

Connecting technology

The main technology of joining PEXCc and PE-RT pipes of the KAN-therm Push system is a clamping technology using an axially pushed-on brass ring. The connection is made by pushing the flared pipe end onto a connector and next pushing on a clamping ring onto this connection. The pipe material is pressed into the connector notches, i.e. the connection is sealed on its entire surface thus a prefect leak-tightness and a long life are guaranteed. This technology does not require any additional seals such as O-rings. There is one more advantage to it, it is not affected by human errors.

1. Cut a PEXCc or a PE-RT pipe at a straight angle to the axis to a required length with a scissors for plastic pipes.

2. Put a ring onto a pipe with the chamfer to the front of the fitting.

3. Fit a head of a proper diameter onto a battery driven or manual expander. Expand the pipe with an expanding tool in three steps. The first two expansions shall be incomplete, with rotation of the expanding tool in relation to the pipe 30 ° and 15 ° after each step. Third expansion of the pipe must be full.

4. Directly (!) after pipe expansion, push a connector into the last notch at the end of a stub pipe of a fitting (do not push the pipe all the way to the fitting flange!).

5. Prior to the pushing step fit the jaws of the press with the right inserts. Push the ring with a hand press (5a) or a foot-driven hydraulic press (5b) or a battery driven press. Fittings can be caught only by their flanges. Do not push on two rings at the same time.

6. The connection is now ready for the pressure test

.png)

Copyright © 2017 KAN Group | All rights reserved. Privacy policy and important information concerning cookies.